Custom transmission belts available

*click on the selected category and see more!

Segment belts

Composite segment belts have been designed to work in harsh conditions and meet the requirements of complex drives.

Lashing belts

Tension belts have been successfully used for years in the coating of cables, pipe profiles and in the processing of plastics.

Toothed belts

We offer polyurethane PU toothed belts: endless, open, with covers, reinforced with steel or Kevlar cord

Flat belts

Flat belts have proven themselves in the world as an indispensable means of transmitting power and transporting various production goods.

PU straps

We offer unlimited possibilities in the selection of polyurethane and polyester transport straps.

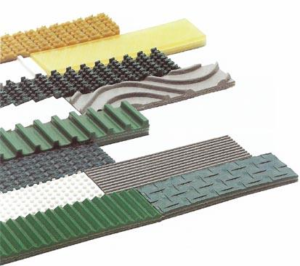

Our company’s offer includes a large selection of transmission belts for various applications. Belts from our assortment can be used to transfer power in machines and industrial devices from various industries. We offer both belts for transferring high rotational speeds and high torque, as well as belts adapted for use in conditions with special requirements. The belts we offer can be made in versions with certificates and approvals for contact with food, with increased resistance to temperature, the action of various chemicals, oils, as well as in variants with increased mechanical strength. Drive belts are also available in versions that allow very precise control of the drive and synchronization of the operation of various components and subassemblies.

Tape and Belt Center offers transmission belts of various types. We have belts in various types: endless, welded, with teeth prepared for gluing or adapted to make a mechanical connection.

The belts we offer include: flat belts. They serve to transmit torque via friction between the driving drum and the wear layer. Thanks to the appropriate belt tension and proper friction, the belt can move the elements of the device without loss of power and with high speeds and significant torques. Flat belts are available in versions using various types of core (e.g. textile or reinforced steel) and protective and running coatings (elastomers, plastics, natural leather or various fabrics).

We also have a wide selection of timing belts. They are offered in different types of toothing, in different materials, and we also have specially reinforced variants. Drive belts use teeth located on the drive member and on the belt to transmit power more efficiently. The drive can be transmitted with high precision, enabling very precise control of the position of the driven element. Such solutions are also used to coordinate various additional cooperating mechanisms.

We also sell guy belts. They are used to guide and tension various semi-finished products undergoing production processes. They can be used to handle various longer elements – cables, metal or plastic profiles, wire or ropes. Lashing belts are produced in various versions, tailored to the needs of a specific application in terms of the shape of the working surface or special reinforcements to increase strength.

Segment belts are also available. They have very good properties comparable to traditional belts, but their great advantage is the possibility of free shaping of their length and replacement, without the need to dismantle the elements of the device in which they are used.

We also offer our customers a large selection of polyurethane straps with high abrasion resistance.