As a standard, drum diameters are determined based on the thickness (number of plies) of the conveyor belt. Additionally, the assumed load is an important factor.

In the table below, a load of 65 – 100% and a standard conveyor were assumed for the calculations.

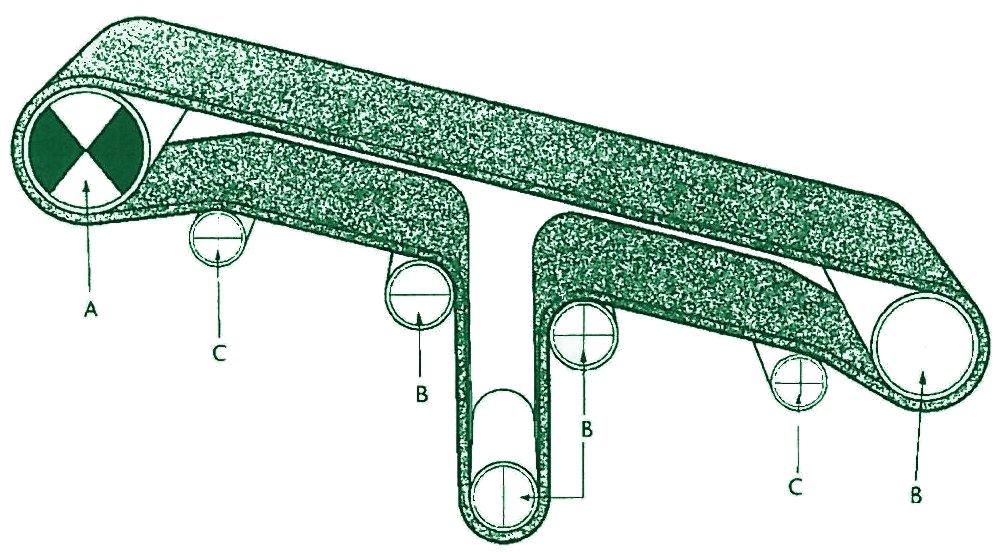

For example, if the longitudinal strength of an EP conveyor belt with 4 plies is 500 N/mm, then the desired values can be found in the table at the intersection of the EP125 column and the row corresponding to the 4 plies. The diameters of drums A, B and C will be 400 mm, 320 mm and 250 mm respectively.

| Number of inserts | EP100 | EP125 | EP160 | EP200 | EP250+EP315 | ||||||||||

A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | |

2 | 160 | 160 | 125 | 200 | 160 | 160 | 250 | 200 | 160 | 320 | 250 | 200 | – | – | – |

3 | 200 | 200 | 160 | 320 | 250 | 200 | 400 | 320 | 250 | 500 | 400 | 320 | 630 | 500 | 400 |

4 | 320 | 250 | 200 | 400 | 320 | 250 | 500 | 400 | 320 | 630 | 500 | 400 | 800 | 630 | 500 |

5 | 400 | 320 | 250 | 500 | 400 | 320 | 630 | 500 | 400 | 800 | 630 | 500 | 1000 | 800 | 630 |

6 | – | – | – | 630 | 500 | 400 | 800 | 630 | 500 | 1000 | 800 | 630 | 1200 | 1000 | 800 |

| *For low belt tension or low belt load, it is acceptable to use smaller drum diameters after consultation | |||||||||||||||