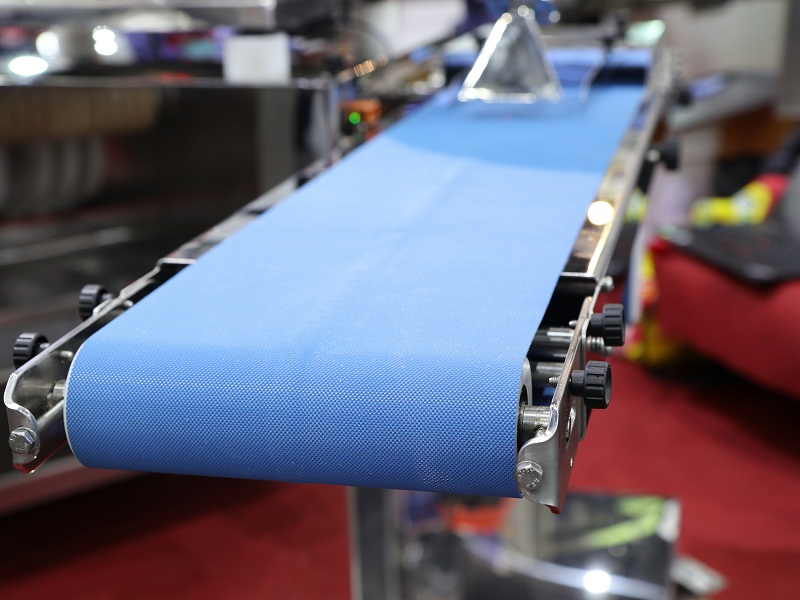

Conveyor belts work well in many enterprises. They are growing in popularity. Their greatest advantages are resistance to harmful chemicals, high temperature and abrasion. They significantly improve every production process.

What are conveyor belts?

Used in many branches of heavy and light industry – food, wood, construction, logistics, etc. They are a necessary element of equipment for machines transporting individual components or entire goods. The decision to choose a specific conveyor belt should be preceded by an analysis of the conditions in which it will be located . We are talking about any impurities, chemical factors and temperature. The type of transported materials also has a significant impact. This is very important, because a properly selected conveyor belt can be used for a long time and without failure . Depending on the requirements imposed by the characteristics of the company’s business profile, tapes with a specific structure and parameters should be used.

How do they work?

It is worth emphasizing that the use of conveyor belts brings many benefits – among other things, thanks to them, the production process runs quickly and efficiently, and materials reach specific positions on time. In addition, they help relieve employees. In return, they can do other jobs that machines can’t do. Versatile use makes the tapes used in more and more objects.

Conveyor belts not only guarantee a change of product location . There are also process belts on the market, on which a number of other activities take place, such as grinding or cooling.

The operation of conveyor belts is very effective – they work well in various conditions, are resistant to abrasion and very durable . Their work is quite silent.