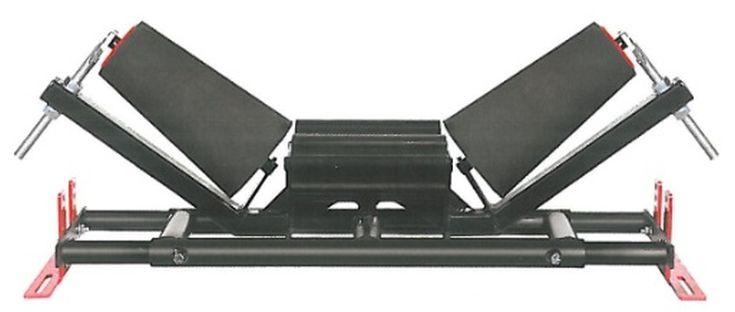

The patented Tru-Trac Taper Trough units offer the most effective belt alignment system in a trough. Top performance is the result of 10 years of designing and testing innovative belt alignment systems. This idler design responds extremely quickly on both loaded and unloaded belts.

Due to the arrangement of the rollers in the entire assembly, the belt can run in both directions. The operation of the belt alignment system is based on coated side rollers that easily operate in the range of 25º – 55º. The side rollers ensure immediate system operation as soon as the belt leaves the center, ensuring that at no point does the edge of the belt come into contact with the 90º rollers.

Exceptional Performance – The combination of tapered side rollers and a unique pivoting center axle ensures quick response in all conditions;

Easy roller replacement – side and center rollers can be replaced one at a time according to wear;

Reinforced central axis – reinforced construction of the rotary axis for fast operation of the belt alignment system;

Standard bearings

– 6205 C3 2RS bearings are used in the trough sets from 600 to 850 mm wide;

– in trough sets from 900 to 1200 mm wide, bearings 6306 C3 2RS were used;

Reinforced bearings – spherical bearings 21308 are used in 1350 to 1800 mm wide basin sets;

Maintenance free – sealed bearings do not require any lubrication;

Cover – Available in 12mm natural rubber abrasion resistant cover or 12mm polyurethane cover (blue). Covers also available in a fireproof version;

Work in all conditions – quick installation possible on wet and dry tapes;

Universal installation – minimal tension is required on the central rollers, which can be easily adjusted using the mounting brackets;

Reversible belts – ideal working properties.

(larger dimensions available on request)