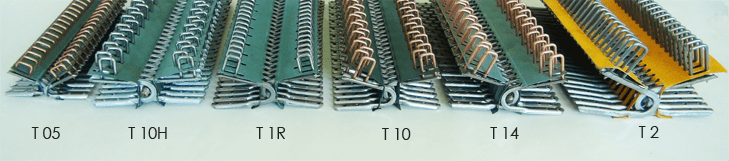

Titan joints produced by MLT Minet Lacing Technology SA are intended for the repair and joining of belts with a thickness of 5-18 mm working under heavy load. Connections are ready for immediate use thanks to pre-assembled staples. An additional advantage of this type of connector is a plastic coating that prevents metal from coming into contact with the transferred objects.

| T10H | T1R | T05 | ||||||||

| T-10-H | Titan-1R | T05 | ||||||||

| Staple size | 20 | 22 | 24 | 26 | 22 | 24 | 26 | 28 | ||

| Tape thickness, mm | 5 – 7.5 | 7.5 – 9.5 | 9.5 – 12.5 | 12.5 – 14 | 6 – 8 | 8 – 10 | 10-12 | 12-14 | 5 – 7 | |

| belt strength , N/mm | 1250 | 1250 | 650 | |||||||

| belt tension , N/mm | 125 | 125 | 65 | |||||||

| Drum min. Ø, mm | 250 | 250 | 80 | |||||||

| Connector material | galvanized carbon or stainless steel | galvanized carbon or stainless steel or stainless non-magnetic steel | stainless steel | |||||||

| bar Ø, mm | 6.0 | 7.0 | 6.0 | 7.0 | 3.0 | 3.2 | ||||

| The material of the stick | hardened stainless steel | hardened stainless steel with or without PA coating | hardened stainless steel | hardened stainless steel with or without PA coating | stainless steel with PA coating | grooved stainless steel | ||||

| T10 | T14 | T2 | ||||||||

| Titan-10 | Titan-14 | Titan-2 | ||||||||

| Staple size | 22 | 24 | 26 | 28 | 24 | 26 | 28 | thirty | 38 | 40 |

| Tape thickness, mm | 6 – 8 | 8 – 10 | 10-12 | 12-14 | 9.5 – 12.5 | 12.5 – 14.5 | 14 – 16 | 16 – 18 | 14 – 16 | 16 – 18 |

| belt strength , N/mm | 1400 | 1600 | 3500 | |||||||

| belt tension , N/mm | 140 | 160 | 350 | |||||||

| Drum min. Ø, mm | 250 | 500 | 800 | |||||||

| Connector material | galvanized carbon or stainless steel or stainless non-magnetic steel | stainless steel | stainless steel | |||||||

| bar Ø, mm | 6.0 | 7.0 | 6.0 | 7.0 | 9.0 | |||||

| The material of the stick | hardened stainless steel | hardened stainless steel with or without PA coating | hardened stainless steel | hardened stainless steel with or without PA coating | hardened stainless steel with or without PA coating | |||||