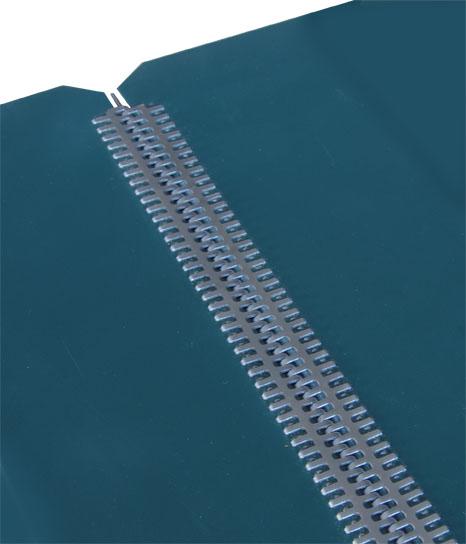

Triangular joints are ideal for connecting leather, cotton and plastic conveyor belts operating under relatively light loads. This connection is characterized by a wide range of tape thicknesses (1-12.5 mm) and ease of assembly.

The most important advantages of triangle connections :

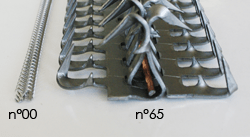

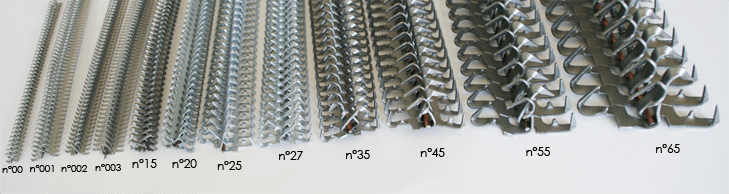

| no. 00 | no. 001 | no. 002 | no. 003 | no. 15 | no. 20 | no. 25 | no. 27 | no. 35 | no. 45 | no. 55 | no. 65 | |

| Tape thickness, mm | 1.0 – 1.5 | 1.5 – 2.0 | 2.0 – 2.5 | 2.5 – 3.5 | 3.0 – 4.0 | 4.0 – 4.5 | 4.5 – 6.0 | 6.0 – 7.0 | 7.0 – 8.5 | 8.5 – 9.5 | 9.5 – 11.0 | 11.0 – 12.5 |

| belt tension , N/mm | 4.3 | 7.8 | 7.8 | 8.7 | 11.4 | 16.6 | 17.5 | 21 | 26 | 28 | thirty | 35 |

| belt strength , N/mm | 43 | 78 | 78 | 87 | 114 | 166 | 175 | 210 | 260 | 280 | 300 | 350 |

| Drum min. Ø, mm | 25 | 25 | 40 | 50 | 65 | 75 | 100 | 130 | 180 | 230 | 300 | 360 |

| Material of manufacture | stainless or galvanized steel | galvanized steel | ||||||||||

| Packaging | 12 slats x 150 mm or 8 slats x 1200 mm | 12 slats x 300 mm or 8 slats x 1200 mm | 16 slats x 200 mm | 10 slats x 300mm | 16 slats x 300mm | 8 slats x 300mm | ||||||