Tru-trac Single Rollers

Standard Flat Return

Heavy Duty Flat Return

Low Speed Flat Return

Polyurethane Flat Return

The most important advantage of Flat Return rollers is their simplicity!

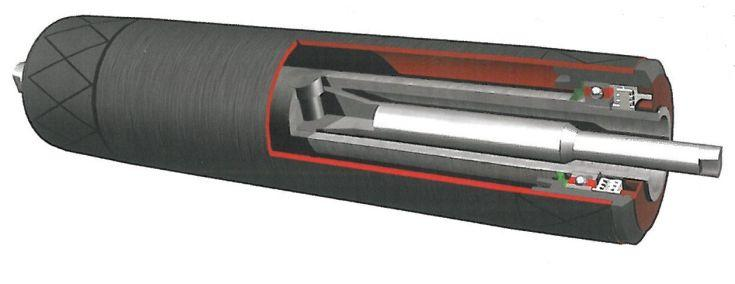

The rollers are made of two components: an inner stationary drum attached to a pin that allows one edge of the roller to swing forward and the other backward and vice versa, exactly in the same plane as the belt, and an outer cylinder that rotates around the inner one (see figure below). The outer cylinder tapers towards the edges, creating a slightly smaller diameter at the ends of the roller than in the middle.

When the tape slides off the center of the roll, it meets the tapered outer edges. As the belt moves over the smaller diameter part of the roller, a difference in frictional force is created which causes that part of the roller to move forward, bringing the tape back to the center.

Single Tru-Trak Roller Versions Available:

| Standard Flat Return | standard roll covered with rubber in dimensions from 300 to 1200 mm |

| Heavy Duty Flat Return | extended, additionally reinforced roller covered with rubber, dimensions from 1350 to 1800 mm |

| Low Speed Flat Return | roll designed for tapes operating at a speed below 1 m/s, dim. from 300 to 1800 mm |

| Polyurethane Flat Return | roll covered with polyurethane for very hard working conditions and very fast tapes, even over 4 m/s, dim. from 300 to 1800 mm |

Information about other products can be found at www.c-t-p.com.pl