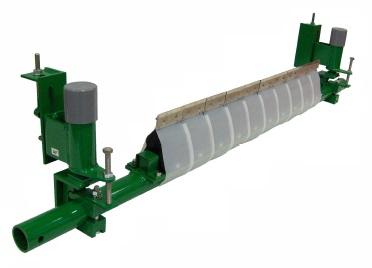

Conveyor belts sometimes run in a trough or suffer irregular wear due to the material being conveyed. Many scraper designs were tested to solve this problem, but they did not fully accommodate belt irregularities. Our new product, BELLE BANNE® TYPE A, is able to deal with this problem thanks to the application of Pascal’s law.

The scraper consists of segmented attachments that individually adapt to a trough or belt failure. Thanks to this, the scraper blades are pressed with even force over the entire width of the belt. The scraper efficiently removes adhering material to the belt to ensure a clean working environment.

Skrobak składa się z podzielonych na segmenty nasadek, które indywidualnie dostosowują się do niecki lub uszkodzenia taśmy. Dzięki temu ostrza skrobaka dociskane są z równomierną siłą na całej szerokości taśmy. Skrobak wydajnie usuwa przylegający do taśmy transportowany materiał aby zapewnić czyste środowisko pracy.

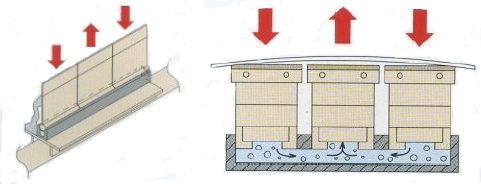

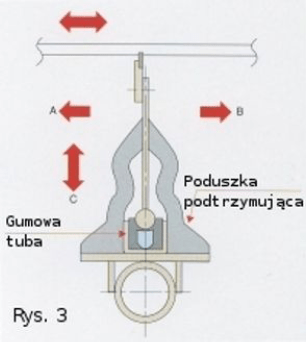

A rubber tube filled with a liquid substance is located below the cushion that supports the BELLE BANNE® A-TYPE scraper blades. When the force acts on the blades where the trough is formed, they adapt to the shape of the belt independently so that the pressure of all scraper blades on the belt is even across the entire width. If, for example, a force is applied to the scraper side pieces (fig. 1, fig. 2), the center pieces lift up to conform to the belt. As a result, the conveyor belt is cleaned across the entire width of the scraper.

The rubber cushions supporting the scraper elements have a wavy shape.

Rubber cushions supporting the scraper elements absorb the pressure from the belt, and the wave shape facilitates precise pressure of the scraper cap to the belt. This shape also helps absorb any A, B, C forces on the scraper.

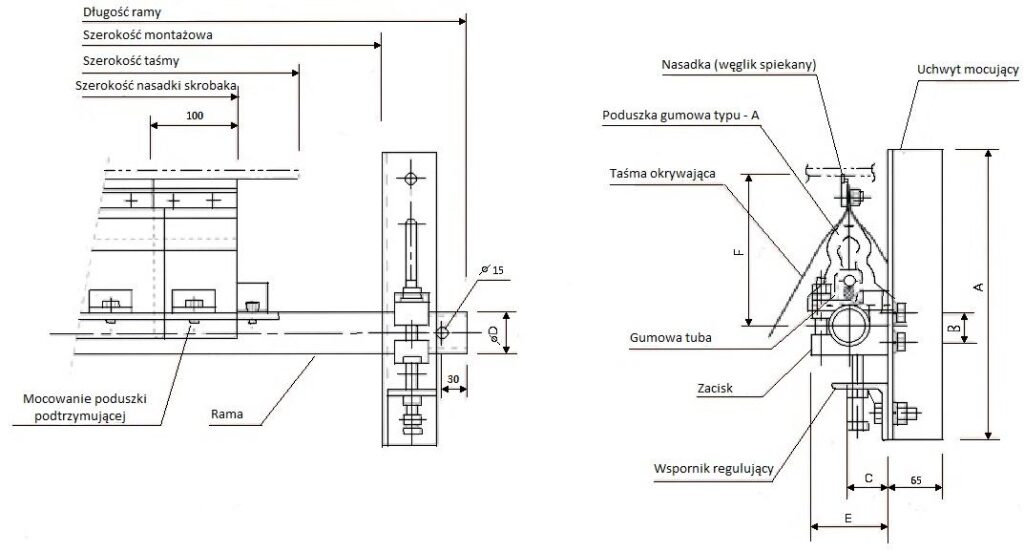

| Model | Tape width | Scraper blade width* | Frame length* | Frame diameter ø D | AND* | b | c | E | f | Weight (kg) |

| A 35 | 350 | 300 | 1100 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 20.0 |

| A 45 | 450 | 400 | 1200 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 22.7 |

| A 50 | 500 | 500 | 1300 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 25.1 |

| A 65 | 650 | 600 | 1450 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 27.8 |

| A 80 | 800 | 700 | 1600 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 30.8 |

| A 90 | 900 | 900 | 1700 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 35.9 |

| A 100 | 1000 | 1000 | 1800 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 38.6 |

| A 105 | 1050 | 1000 | 1900 | ø 48.6 | 350 | 40 | 46 | 92 | 187 | 39.1 |

| A 120 | 1200 | 1200 | 2100 | ø 60.5 | 350 | 50 | 52 | 104 | 193 | 48.4 |

| A 135 | 1350 | 1300 | 2250 | ø 60.5 | 350 | 50 | 52 | 104 | 193 | 51.7 |

| A 140 | 1400 | 1400 | 2300 | ø 60.5 | 350 | 50 | 52 | 104 | 193 | 54.1 |

| A 150 | 1500 | 1500 | 2400 | ø 60.5 | 350 | 50 | 52 | 104 | 193 | 57.7 |

| A 160 | 1600 | 1600 | 2500 | ø 60.5 | 350 | 50 | 52 | 104 | 193 | 60.6 |

| A 180 | 1800 | 1800 | 2700 | ø 76.3 | 400 | 55 | 65 | 130 | 201 | 84.3 |

| A 200 | 2000 | 2000 | 3100 | ø 76.3 | 400 | 55 | 65 | 130 | 201 | 90.2 |

| A 220 | 2200 | 2200 | 3300 | ø 76.3 | 400 | 55 | 65 | 130 | 201 | 99.3 |