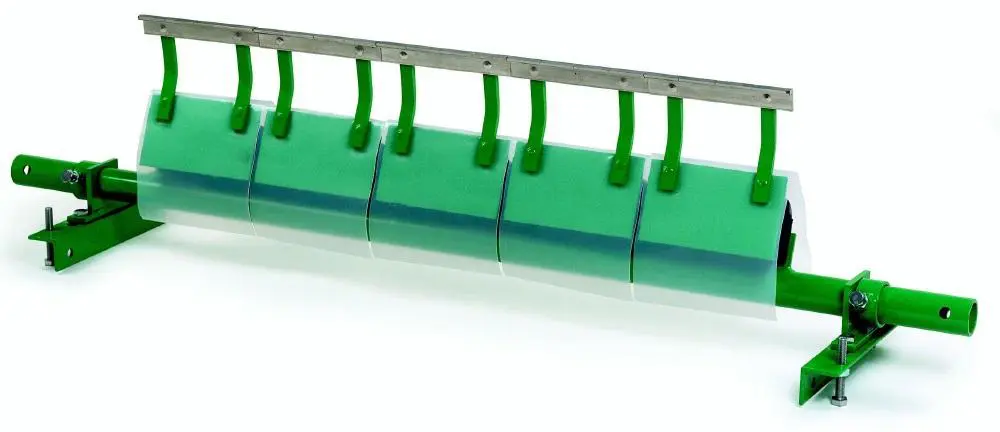

The H-type front scraper is intended for use in conveyors where P-type scrapers cannot be used due to the reversible operation and the lack of technical possibilities to place the scraper under the conveyor. The maximum belt speed is 3.5 m/s.

To use Belle Banne H-TYPE, the conveyor belt must be well cured and without mechanical joints. An important installation parameter is the diameter of the drum on which the scraper will be mounted (from 250 to 1700 mm).

The Belle Banne H-TYPE scraper is designed to be used as a pre-scraper before the P-type precision scraper. In fact, however, it is sufficiently effective that no additional scrapers are needed. It is often the only possible solution for cleaning the belt due to the impossibility of installing scrapers under the conveyor. It should be used on straight drums. For convex drums, consult your Belle Banne representative beforehand.

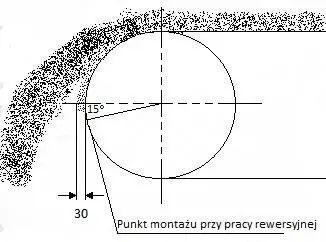

If the transported material is very sticky and adheres to a thickness of more than 30 mm at the point marked in the figure, the H-type scraper may not work properly and installation is not recommended in such a situation.

The maximum belt speed is 320 m/min. Do not install this type of scraper on belts with damaged surfaces or mechanical joints.

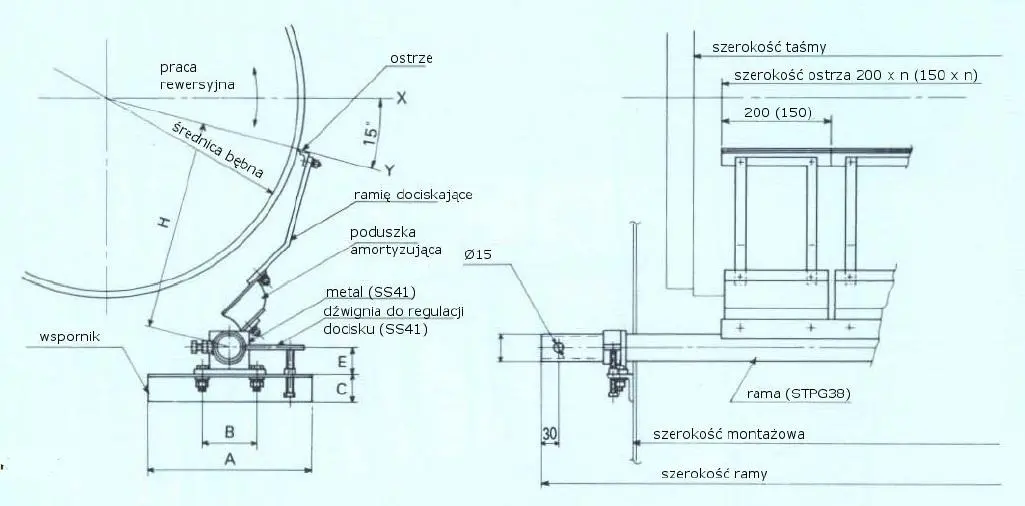

Belle Banne H-TYPE scrapers can be installed on reversing conveyors. The cleaning blade should be 15º below the horizontal line through the center of the drum (Fig. above). If installed inside the chute, side holes may need to be cut to install the scraper.

The wear of the blades depends on the applied clamping force, the type of transported material, its shape and size, humidity and the size of the blades.

| Model | Tape width | Blade width | The number of blade elements | Blade element width | Frame length | AND | b | c | d | E | Weight (kg) |

| 35H | 350 | 300 | 2 | 150 | 850 | 300 | 100 | 50 | 42.7 | 49 | 15.8 |

| 45H | 450 | 450 | 3 | 150 | 950 | 300 | 100 | 50 | 42.7 | 49 | 17.7 |

| 50H | 500 | 450 | 3 | 150 | 1000 | 300 | 100 | 50 | 42.7 | 49 | 18.5 |

| 65H | 650 | 600 | 4/3 | 150/200 | 1150 | 300 | 100 | 50 | 42.7 | 49 | 21/22.5 |

| 80H | 800 | 750/800 | 5/4 | 150/200 | 1300 | 300 | 100 | 50 | 42.7 | 49 | 24/23.5 |

| 90H | 900 | 900/800 | 6/4 | 150/200 | 1400 | 300 | 100 | 50 | 42.7 | 49 | 27/27.5 |

| 100H | 1000 | 900/1000 | 6/5 | 150/200 | 1500 | 300 | 100 | 50 | 48.6 | 49 | 29/32.5 |

| 105H | 1050 | 1050/1000 | 7/5 | 150/200 | 1600 | 300 | 100 | 50 | 48.6 | 49 | 32/33.5 |

| 120H | 1200 | 1200/1200 | 8/6 | 150/200 | 1800 | 300 | 100 | 50 | 48.6 | 49 | 35/37.5 |

| 140H | 1400 | 1400 | 7 | 200 | 2000 | 350 | 150 | 65 | 60.5 | 59.5 | 51.5 |

| 150H | 1500 | 1400 | 7 | 200 | 2100 | 350 | 150 | 65 | 60.5 | 59.5 | 53 |

| 160H | 1600 | 1600 | 8 | 200 | 2200 | 350 | 150 | 65 | 60.5 | 59.5 | 57.5 |

| 180H | 1800 | 1800 | 9 | 200 | 2500 | 350 | 150 | 65 | 76.3 | 67 | 74.5 |

| 200H | 2000 | 2000 | 10 | 200 | 2900 | 350 | 150 | 65 | 76.3 | 67 | 80 |

| 220H | 2200 | 2200 | 11 | 200 | 3100 | 350 | 150 | 65 | 76.3 | 67 | 88.5 |